How to Inspect Your Small Engine for Brake Replacement

In most walk mowers, a well-maintained brake system should stop the engine and any attached cutting equipment within three seconds whenever you step away from the equipment or release the brake bail. If the engine operates for more than three seconds after braking, then the stop switch or brake pad/band may be in need of replacement or adjustment.

Follow our step-by-step engine brake inspection and replacement guide for both pad and band style or jump to the most relevant section below:

Servicing Engine Brake Pads in Mowers & Outdoor Power Equipment

How to Remove Brake Pads for Inspection

How to Inspect and Test Brake Pads for Replacement

How to Reassemble the Brake System

How to Remove And Inspect Band Brakes for Replacement

How to Test Band Brakes

How to Assemble Band Brakes After Inspection

![]() WARNING: Always read the engine and equipment manual(s) before starting, operating, or servicing your engine or equipment to avoid personal injury or property damage. See an authorized dealer or contact Briggs & Stratton if you are unsure of any procedure or have additional questions. Find all Engine Safety Warnings

WARNING: Always read the engine and equipment manual(s) before starting, operating, or servicing your engine or equipment to avoid personal injury or property damage. See an authorized dealer or contact Briggs & Stratton if you are unsure of any procedure or have additional questions. Find all Engine Safety Warnings

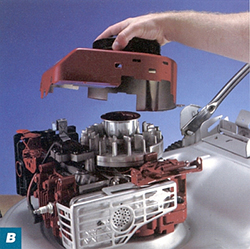

- Step 2: Remove the brake control bracket cover, if equipped. Then, loosen the cable clamp screw and remove the brake cable from the control lever.

- Step 3: Disconnect the spring from the brake anchor, using needlenose pliers . Then, remove the stop switch wire by gently squeezing the switch and pulling lightly on the wire until it slips free. If the engine is equipped with an electric starter motor, disconnect the pair of wires leading to the starter motor.

- NOTE: Measure the pad only, not the bracket. Replace the brake assembly if the pad's thickness is less than .090".

- Step 2: Test the stop switch using a multitester or ohmmeter, to determine whether the ignition circuit is grounded when the stop switch is activated.

The stop switch should show continuity (0 ohms) to engine ground when the switch is set to STOP, and no continuity (∞), when the switch is set to RUN. If you identify a problem, check for loose or faulty connections.

Once you’ve completed the inspection, replace brake pads as needed. If you continue experiencing problems, reach out to your Briggs & Stratton Dealer for additional repair help!

How to Reassemble the Brake System

- Step 1: Install the brake assembly on the cylinder.Tighten the mounting bolts to 40 inch. lbs. with a torque wrench.

- Step 2: Install the stop switch wire by bending the end of the wire 90°

- Step 3: Install the blower housing and any other engine parts removed for brake servicing.

- Step 4: Check the brakes by pivoting the lever. Make sure the lever moves freely and the pad makes full contact with the flywheel.

- Step 5: Attach the brake spring using needlenose pliers and connect the brake cable

- Step 6: Test the braking system by starting the engine and then releasing the brake bail. The engine and the blade or other equipment should come to a stop within three seconds.

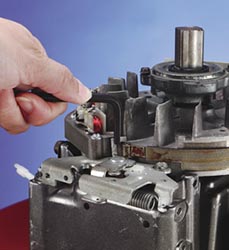

- Step 2: Release the brake spring using pliers

- Step 3: Lift the brake band off the stationary and movable posts

- Step 4: Inspect and replace the band if you find nicks or cuts.

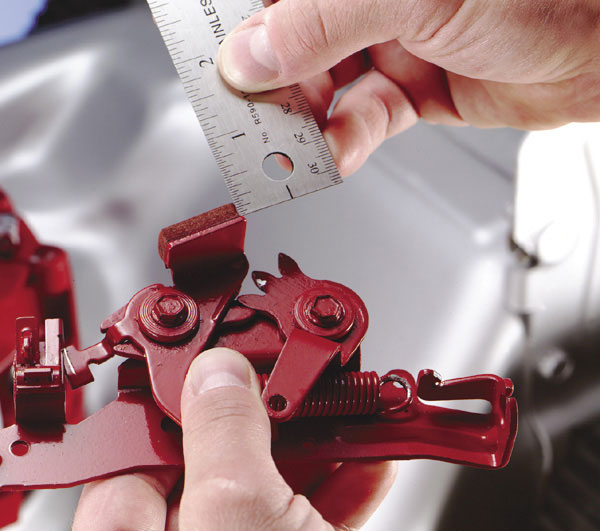

- Step 5: Check for wear by measuring the band’s thickness with a ruler or caliper

- NOTE: Measure the brake pad only, not the metal band. Replace the brake band if the pad's thickness is less than .030"

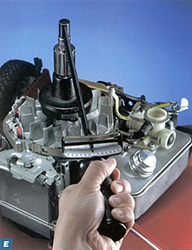

Test the band brake's stopping power with the spark plug lead secured away from the spark plug. On electric start engines, disconnect and remove the battery.

- Step 1: With the brake engaged, turn the starter clutch, using a starter clutch adapter and torque wrench.

If the torque reading is lower than 45 inch lbs. while turning the flywheel clockwise at a steady rate, the engine components may be worn, damaged or in need of adjustment.

- Step 2: Test the stop switch with a multitester or ohmmeter to determine whether the ignition circuit is grounded when the stop switch is activated. The stop switch should show continuity (0 ohms) to engine ground when the switch is set to STOP, and no continuity (∞) when the switch is set to RUN. If you discover a problem, check for loose or faulty connections.

Contact a Briggs & Stratton dealer for brake adjustment or addressing connection issues. Check out our FAQ on ignition system problems for additional maintenance and repair help.

How to Assemble Band Brakes After Inspection

- Step 1: Reinstall the stop switch wire on the control bracket. On older systems, reinstall the stop switch wire on the control bracket stop switch terminal.

- Step 2: Place the band brake on the stationary post and hook it over the end of the movable post until the band bottoms out.

- NOTE: The brake material on a steel band must be on the flywheel side after assembly. On older systems, install the band brake on the stationary and movable posts.

- Step 3: Bend the retainer tang until it is positioned over the band brake loop so that the loop cannot be accidentally dislodged. After assembly, check that the braking material on the metal band faces the flywheel.